Apprentice Life at Mecmesin

Kara, Digital Marketing Apprenticeship

|

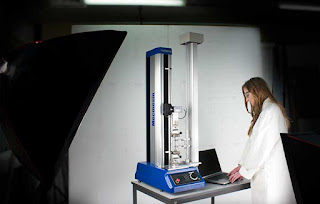

| Kara working on product brochure assets |

University isn’t for everyone and having worked within a digital marketing role for almost two years prior to joining Mecmesin I was keen not to be ‘pigeon-holed’ within the industry. In hope to grow and strengthen my skill-set I joined as an apprentice, which would not only give me a role to fulfil this but also a qualification I could take forward with me.

Although on release to college one day a week, my role at Mecmesin was not limited. Throughout completing my apprenticeship training I was given the opportunity to get hands on experience in areas that coincided with my study. As a global company with multiple subsidiaries Mecmesin has given me the perfect foundation to work across a breadth of projects providing the varied role I’d been craving!

Responsibilities in the Marketing Department

|

| The published work |

Having now developed within my role, I am responsible for the contribution, maintenance, and development of digital projects and campaigns across; Email Marketing, Search Engine Optimisation, Pay-Per-Click, and Social Media. From these campaigns I am tasked with monitoring key performance indicators and producing reports to demonstrate effective return on investment – something I find very rewarding as it allows me to see exactly how my efforts are benefiting the company.

Full time career

|

| Product launch at Control 2017 |

Despite my apprenticeship programme being purely based on the digital aspect of marketing, I was also given the chance to assist with the organisation of exhibitions. This has introduced me to a whole new aspect of marketing, and really helped to build my confidence after I attended the launch of our new product range at the Control show in Germany May last year.

Originally this role was a placement that allowed me to complete my Level 3 Diploma in Digital Marketing, but now it is a role that is growing with me and I am a happy full-time employee.

Check out our careers page for apprenticeship opportunities!